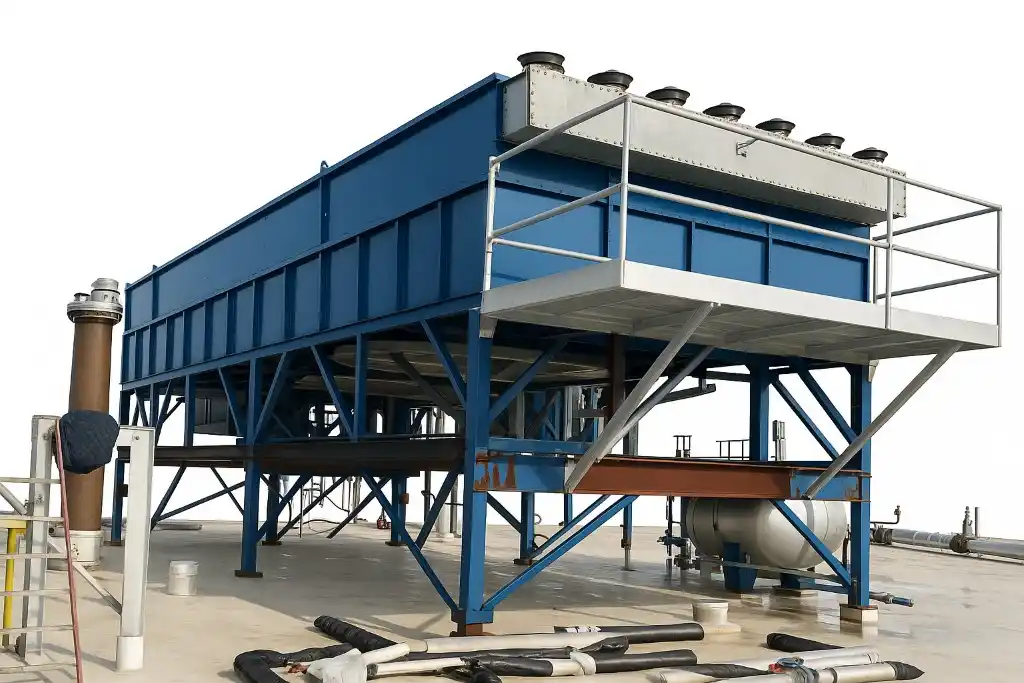

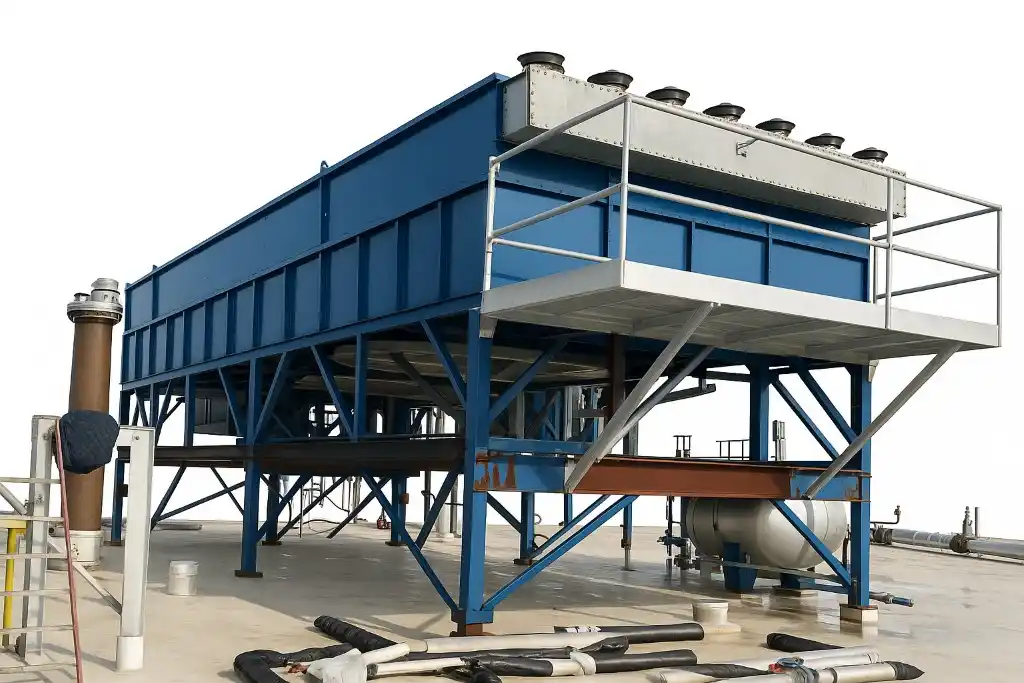

An Air Fin Cooler is an industrial heat exchanger that cools process fluids like oil, gas, or chemicals using ambient air instead of water. It's also known as an Air Cooled Heat Exchanger (ACHE) and is commonly used in refineries, chemical plants, power stations, and offshore installations. The hot fluid passes through finned tubes while large fans blow air across them, removing heat and cooling the fluid inside without any water consumption.

How Does an Air Fin Cooler Work Step by Step?

- Hot Fluid Inlet :The heated process fluid flows into the network of finned tubes to begin the cooling process.

- Heat Transfer : Heat travels from the fluid to the fins through the tube walls.

- Air Circulation : High-capacity fans move cool outside air over the finned surfaces, enabling efficient heat removal from the heated fluid inside the tubes.

- Cooling Action :The air absorbs the heat and leaves at a higher temperature.

- Cooled Fluid Exit : The now-cooled fluid exits and continues to the next stage of the process.

This process is based on convective heat transfer and is highly efficient, especially in dry or remote environments.

What Are the Main Components of an Air Fin Cooler?

- Finned Tubes :Boost heat transfer by increasing surface area.

- Tube Bundle : A network of finned tubes through which the fluid flows.

- Fans (Axial or Centrifugal) : Drive air across the finned tubes.

- Headers/Manifolds : Distribute and collect the fluid.

- Plenum Chamberx : Directs air over the tube bundle.

- Louvers and Dampers : Regulate airflow and direct air across the cooling surface.

- Frame/Structure : Mounts and supports the entire system.

What Types of Air Fin Coolers Are Available?

By Airflow Design:

- Forced Draft Coolers : Fan blows air into the fin bundle.

- Induced Draft Coolers : Fan pulls air through the bundle.

- Natural Draft Coolers : No fan; relies on natural airflow.

By Tube Orientation:

- Horizontal Type

- Vertical Type

- V-Type (A-Frame)

Each type is selected based on process needs, installation space, and performance expectations.

Why Use Air Fin Coolers Instead of Water Cooling Systems?

- No water required – Perfect for water-scarce regions.

- Low environmental impact – No effluent or chemical discharge.

- Low maintenance – No scaling, fouling, or water treatment.

- Energy-efficient operation – Especially with VFD fans.

- Cost-effective – Reduced lifecycle costs compared to cooling towers.

Where Are Air Fin Coolers Used?

| Industry |

Application |

| Oil & Gas | Crude, natural gas, lube oil cooling |

| Petrochemical | Process and gas phase cooling |

| Fertilizers | Ammonia and urea plants |

| Power Generation | Transformer and turbine oil cooling |

| Refineries | Heat removal from hydrocarbon fluids |

| Steel Plants | Gas, blast furnace cooling |

What Materials Are Used in Air Fin Coolers?

- Tubes: Carbon steel, stainless steel, copper alloys

- Fins: Aluminum, copper, carbon steel

- Structure: Galvanized or painted steel

Material selection depends on the fluid’s temperature, pressure, and corrosiveness.

What Are the Advantages of Air Fin Coolers?

- Water-Free Cooling

- Lower Operational Costs

- Environmental Compliance

- Space-Saving Designs

- Modular and Expandable

How Do You Select the Right Air Fin Cooler?

- Process fluid type and properties

- Required outlet temperature

- Flow rate (mass or volume)

- Site conditions (temperature, altitude)

- Installation space

- Noise limits (for populated areas)

What Are Common Problems with Air Fin Coolers and Their Solutions?

| Problem | Cause | Solution |

|---|

| Dust and dirt clog fins | Airborne particles | Periodic cleaning using air/water |

| Fan vibration or noise | Imbalance or bearing wear | Regular inspection & lubrication |

| Uneven cooling | Blocked tubes or headers | Internal cleaning or inspection |

| Corrosion | Poor material match or coating | Use corrosion-resistant materials |

What Maintenance Is Required for Air Fin Coolers?

- Inspect fan belts and bearings.

- Clean fins and tube surfaces.

- Check motor wiring and insulation.

- Inspect tube bundle for corrosion or leaks.

- Monitor header gaskets and replace if worn.

How Do Air Fin Coolers Compare with Other Heat Exchangers?

| Feature | Air Fin Cooler | Shell & Tube | Cooling Tower |

|---|

| Water Use | None | High | Very High |

| Maintenance | Low | Medium | High |

| Location | Outdoor | Indoor/Outdoor | Outdoor + Basin |

| Energy Cost | Medium | Low | High |

| Environmental Impact | Low | Medium | High |

Are Air Fin Coolers Energy Efficient?

- Variable Frequency Drives (VFDs) on fans

- Low-resistance fin designs

- Efficient tube layouts

- Proper maintenance routines

What Standards Govern the Design of Air Fin Coolers?

- API 661 – Design standards for air-cooled heat exchangers in oil, gas, and chemical industries.

- ASME Section VIII – Pressure Vessel Code

- TEMA – Tubular Exchanger Manufacturers Association guidelines

What Are the Latest Innovations in Air Fin Coolers?

- IoT-based monitoring – Real-time diagnostics

- High-Efficiency EC Fans – Strong airflow with low power use

- AI-based fault detection – Predictive maintenance

- Eco-coatings – Longer corrosion resistance

- Modular skids – Easy installation

Where to Buy Air Fin Coolers

If you're looking for high quality Air Fin Coolers, United Cooling Systems is a trusted manufacturer and supplier with a proven track record in delivering reliable, energy-efficient cooling solutions. Whether you need standard models or fully customized units, United Cooling Systems offers products designed to meet stringent industrial demands across sectors like power generation, oil & gas, petrochemical, and manufacturing.

Why Choose United Cooling Systems?

- ISO-certified manufacturing with strict quality control

- Custom-engineered solutions based on your process requirements

- Global delivery and after-sales support

- Durable construction for harsh outdoor and process conditions

- Expert technical consultation and responsive customer service

- Combines innovation with performance to deliver air fin coolers that maximize thermal efficiency and service life

Get in Touch

Air Fin Coolers are an efficient and eco-friendly way to cool industrial fluids using air instead of water. They help save water, reduce maintenance, and are ideal for use in oil & gas, petrochemical, power, and many other industries. With the right design and regular maintenance, they offer reliable performance and long service life. If you're looking for a cost-effective and sustainable cooling solution, an air fin cooler is a smart choice.

- What is an Air Fin Cooler?

An Air Fin Cooler is a device that cools hot fluids using air instead of water. It uses fans to blow air over finned tubes that carry the fluid.

- Where are Air Fin Coolers used?

They are used in oil refineries, chemical plants, power stations, and other industries to cool oil, gas, and other fluids.

- Why are Air Fin Coolers better than water cooling?

They save water, need less maintenance, and work well in dry areas where water is hard to find.

- How do I maintain an Air Fin Cooler?

You should clean the fins, check the fans, and inspect for leaks or corrosion regularly to keep it working properly.

- How long do Air Fin Coolers last?

When well-maintained, their service life can range from 15 to 25 years.