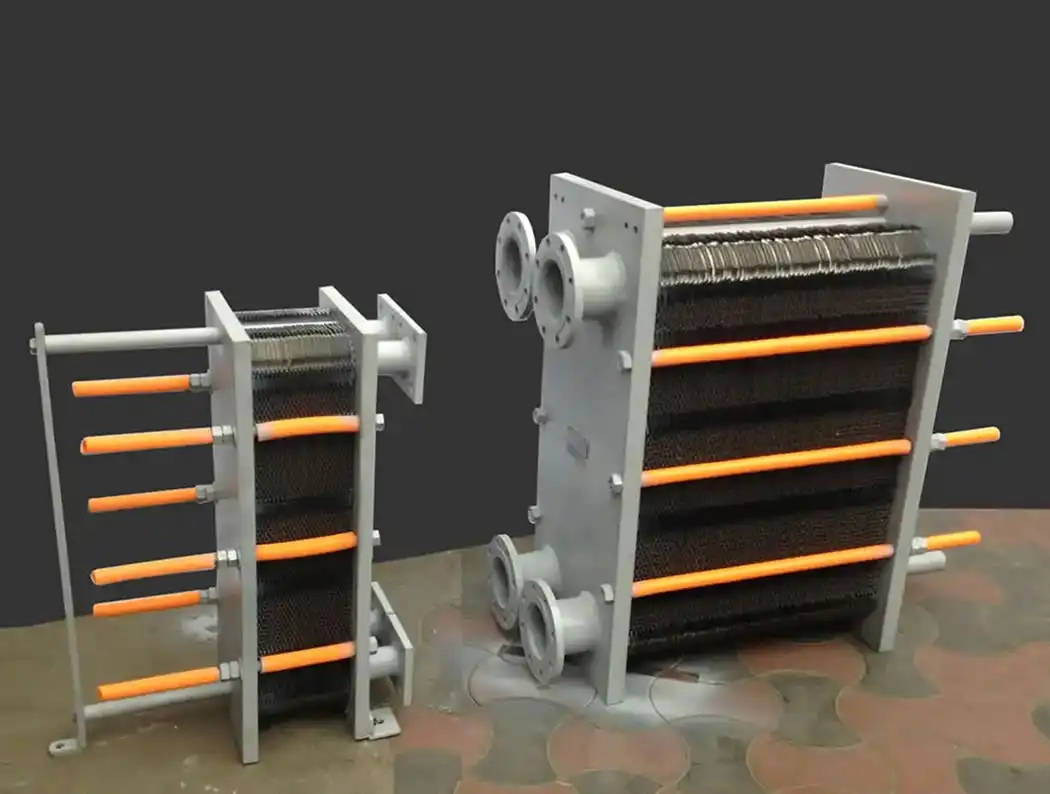

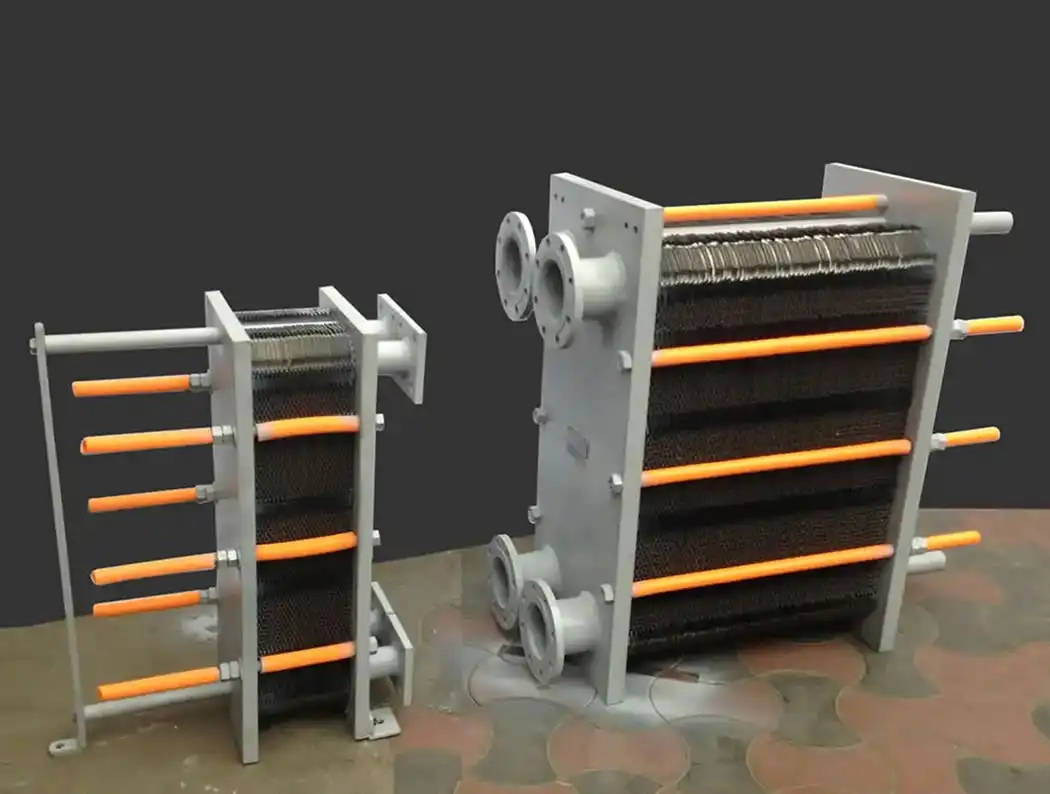

Brazed Plate Heat Exchanger

A brazed plate heat exchanger is a compact, high-efficiency device designed to transfer heat between two separate fluid streams without allowing them to mix. It is widely used in heating, cooling, and industrial systems due to its space-saving design and excellent thermal performance.

Construction and Materials

-

Plates: Thin, stainless steel plates with a chevron pattern to enhance turbulence and heat transfer.

-

Brazing Material: Copper (for general use) or nickel (for corrosive environments) fuses the plates together.

-

Port Holes: Located at the corners to allow the flow of fluids.

-

The plates are stacked with alternate flow directions, then brazed in a vacuum furnace to create a rigid, pressure-resistant block.

Key Features:

- No gaskets (unlike gasketed plate heat exchangers)

- Compact and lightweight

- Capable of withstanding high pressures and temperatures

-

Brazed plate heat exchangers (BPHEs) function based on the principle of indirect heat transfer, where hot and cold fluids enter through opposite ports and exchange heat without direct contact. The design channels them through alternate plates, creating a counterflow or crossflow arrangement.

- Hot fluid loses heat as it passes between two cold fluid plates.

- Cold fluid gains heat via conduction through the thin metal plates.

- Turbulent flow within each channel improves heat transfer efficiency and reduces fouling.

- This design enables highly efficient heat transfer within a compact and space-saving unit.

Types of Brazed Plate Heat Exchangers

Single-Circuit BPHE

- One fluid stream on each side

- Standard use in HVAC and water heating

Multi-Circuit BPHE

- Multiple fluid streams

- Common in chillers and heat pumps

Double Wall BPHE

- Dual plates to detect leakage

- Ideal for potable water systems to prevent contamination

- High Thermal Efficiency: Chevron plate patterns induce turbulence, maximizing surface contact and heat transfer.

- Compact Design: Space-saving, ideal for tight installations.

- Durability: The brazing process eliminates the need for gaskets, reducing failure points.

- Low Maintenance: Fewer parts and robust design lead to reduced servicing.

- Cost-Effective: Competitive pricing due to simple design and ease of manufacturing.

- Versatile Mounting: Can be installed vertically or horizontally.

HVAC Systems

- Used in chillers, boilers, and district heating systems

- Transfers heat between water and refrigerant or between water and glycol

Refrigeration

- Acts as an evaporator or condenser in refrigeration cycles

- Suited for both industrial and commercial cooling units

Renewable Energy

- Transfers heat in solar thermal systems

- Used in biomass boilers and geothermal systems

Industrial Processes

- Cools machinery oil, chemicals, and process fluids

- Applied in plastic molding, pharmaceuticals, and food processing

Marine Applications

- Compact and resistant to harsh marine environments

- Used for engine cooling and desalination

Flow Configuration

- Counterflow: Most efficient; fluids flow in opposite directions.

- Parallel Flow: Simpler design but less thermal efficiency.

Pressure Drop

- Needs to be balanced with desired heat transfer rates.

- High turbulence increases heat exchange but also pressure loss.

Plate Material

- Stainless Steel: Standard for most applications

- Titanium: For seawater and aggressive chemicals

Brazing Material

- Copper: Common and cost-effective

- Nickel: Used for applications with high corrosion risk

Fouling and Maintenance

- Fouling can reduce heat transfer over time.

- BPHEs are less prone to fouling due to turbulence but may still require chemical cleaning.

Installation and Operation

Mounting Orientation

- Vertical mounting preferred to aid natural drainage.

- Avoid air pockets and stagnant zones.

Flow Direction

- Counterflow yields higher thermal efficiency.

- Confirm port connections to match system flow layout.

Operating Parameters

- Confirm temperature and pressure limits.

- Use strainers and filters upstream to reduce particulate contamination.

Startup and Shutdown

- Gradually introduce fluids to avoid thermal shock.

- Avoid sudden pressure changes to protect the brazing joints.

Routine Inspection

- Check for leakage, corrosion, or unusual pressure drops.

Cleaning

- Chemical descaling recommended for scale or fouling.

- Backflushing may be used for moderate debris removal.

Leak Testing

- Periodic pressure tests help detect internal cracks.

Preventive Measures

- Install filters or strainers upstream.

- Use water treatment systems to control scaling.

Limitations and Challenges

- Not Easily Serviceable: Unlike gasketed heat exchangers, BPHEs cannot be disassembled.

- Sensitive to Water Quality: Hard water or aggressive chemicals can lead to scaling or corrosion.

- Pressure Drop Considerations: Improper design may cause excessive pressure loss.

- Thermal Fatigue: Repeated thermal cycling can cause cracks over time.

- Contamination Risk: In case of internal failure, fluids can mix.

- Sensors to track flow rates, temperature differential, and pressure drop

- Enables predictive maintenance and reduces downtime

Enhanced Chevron Designs

- Modified patterns improve thermal performance without increasing pressure loss

Advanced Brazing Materials

- New alloys offer better corrosion resistance and mechanical strength

Modular Configurations

- Custom plate packs for specific thermal loads

- Swappable designs for field replacement

Environmental and Energy Considerations

- Energy Savings: High efficiency reduces energy use in heating and cooling applications.

- Material Efficiency: Minimal use of metal for maximum surface area.

- Longer Lifespan: Reduces waste from frequent replacements.

- Lower Carbon Footprint: Efficient heat transfer results in reduced fuel or power usage.

Brazed plate heat exchangers provide an efficient and space-saving solution for heat transfer across a wide range of industries. Their unique construction allows for high thermal performance, long service life, and versatility in applications ranging from household HVAC systems to demanding industrial and marine settings.

While they are not serviceable like gasketed exchangers, their cost-effectiveness, durability, and performance make them the preferred choice in many situations. With the integration of smart sensors, advanced materials, and optimized designs, the future of BPHEs is firmly aligned with energy efficiency, reliability, and sustainability.

Understanding their design, limitations, and operational nuances ensures better implementation, improved system performance, and long-term cost savings.

Frequently Asked Questions (FAQs)

-

What is the maximum pressure a BPHE can handle?

Typically up to 30 bar (435 psi), depending on size and design.

-

Can BPHEs be used with dirty fluids?

They are best suited for clean fluids; use filters to avoid clogging.

-

How do you clean a brazed plate heat exchanger?

Chemical cleaning or flushing with cleaning agents is recommended.

-

Are BPHEs suitable for steam applications?

Yes, provided they are designed for the pressure and temperature range of steam.

-

What is the lifespan of a BPHE?

Typically 10–20 years, depending on fluid quality and operating conditions.

-

What causes BPHE failure?

Thermal fatigue, pressure surges, scaling, corrosion, or internal cracking.

-

Can I use a BPHE in a vertical position?

Yes, vertical mounting is preferred for effective drainage and air removal.

-

Are BPHEs recyclable?

Yes, made primarily of stainless steel and copper or nickel, they are recyclable.

-

What’s the difference between a BPHE and a gasketed plate heat exchanger?

BPHEs are sealed and compact, while gasketed units are larger and serviceable.

-

Can BPHEs be used in potable water systems?

Yes, especially double-wall BPHEs designed to prevent cross-contamination.