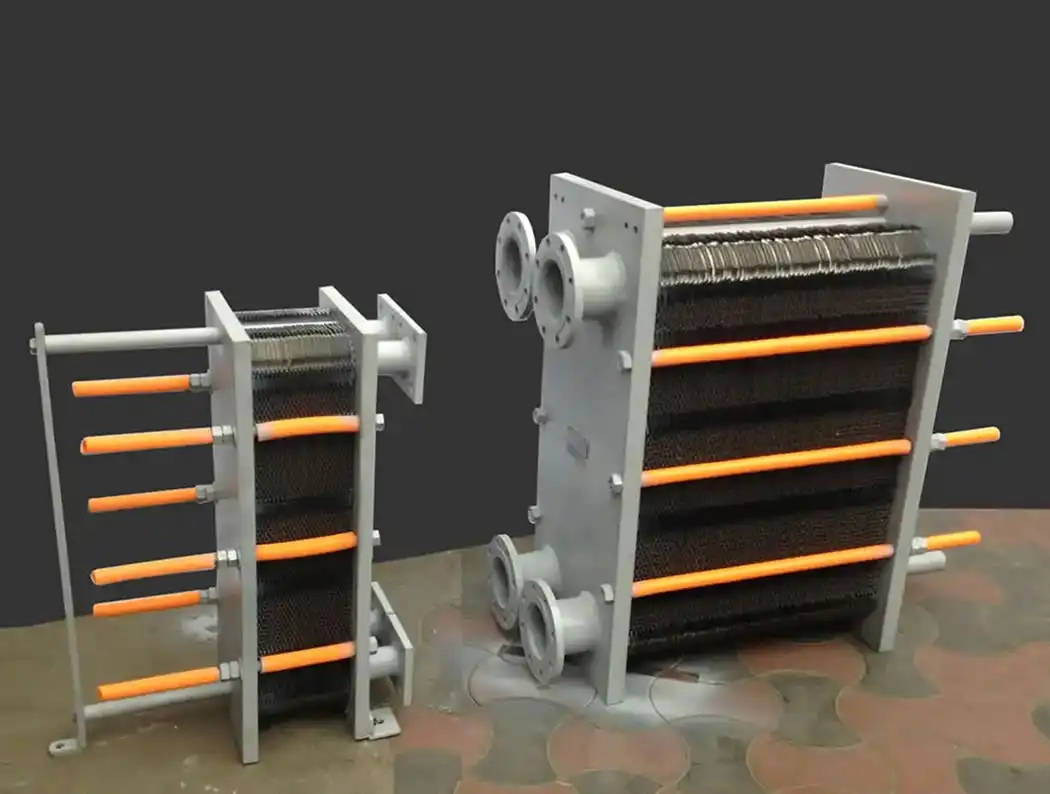

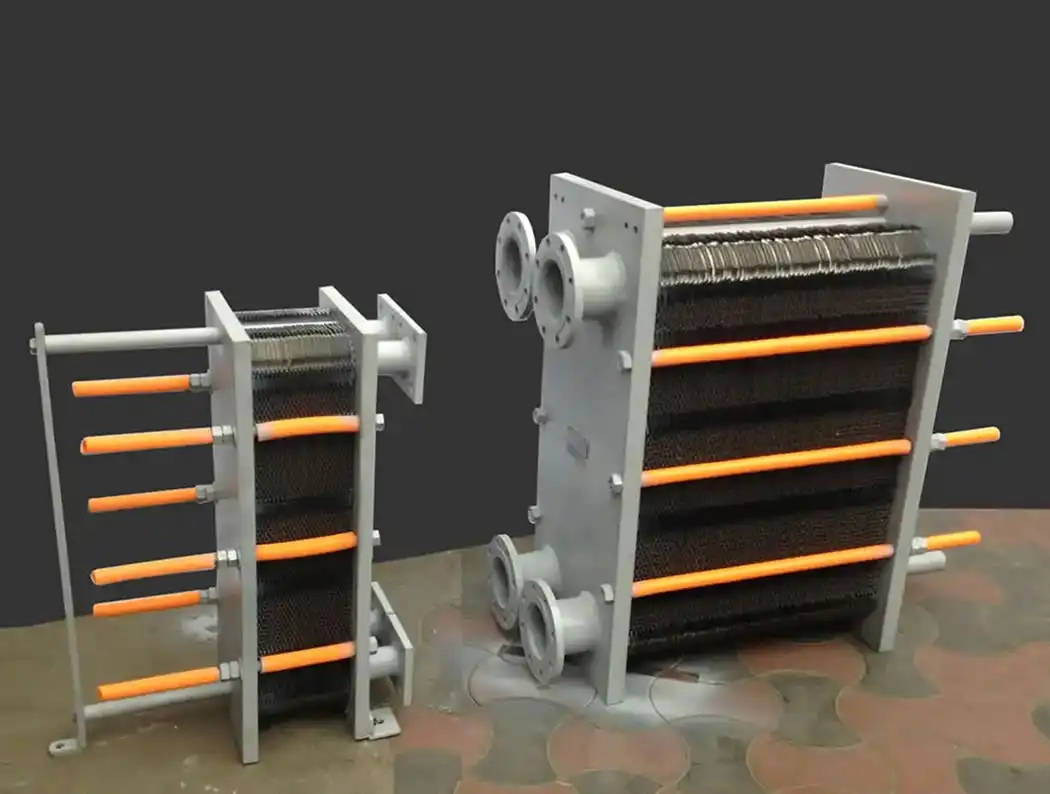

Plate Type Heat Exchanger

A plate type heat exchanger is a device that transfers heat between two fluids using thin, corrugated metal plates. The fluids flow in alternate spaces between the plates, and heat is exchanged through the metal surface. This design maximizes surface area and enhances heat transfer rates, often making PHEs more efficient than traditional shell and tube exchangers in low to medium pressure applications.

How Does a Plate Type Heat Exchanger Work?

A Plate Type Heat Exchanger (PHE) works by transferring heat between two fluids through a series of thin, corrugated metal plates, without the fluids mixing.

Structure Overview

- Made of multiple thin metal plates (usually stainless steel) stacked together.

- Plates are sealed with gaskets (in gasketed PHEs) or welded/brazed in other designs.

- Each plate has a pattern of ridges or corrugations to create turbulence and increase heat transfer efficiency.

Two Separate Fluid Paths

In a plate type heat exchanger, the plates are strategically arranged in a stacked sequence, creating alternating channels for hot and cold fluids.

- Gaskets (or welds) guide each fluid along its path without mixing them.

Hot Fluid Inlet

- Hot fluid enters through an inlet port and flows between specific plates.

- It stays in its own sealed channels.

Cold Fluid Inlet

- Cold fluid enters through a different inlet port and flows in the channels next to the hot fluid channels.

Heat Transfer Process

- Heat moves through the thin metal plates from the hot fluid to the cold fluid by conduction.

- The turbulence created by the plate’s corrugations enhances convection, making heat transfer faster and more efficient.

Why Choose Plate Type Heat Exchanger Over Water Cooled Systems?

- Higher Heat Transfer Efficiency: The thin plates create large surface area and turbulence, so heat transfers faster than in bulky water-cooled systems.

- Compact & Space-Saving: A PHE can be much smaller and lighter while doing the same job as a large shell-and-tube or water-cooled unit.

- Easy Maintenance & Cleaning: Gasketed PHEs can be opened, plates removed, and cleaned quickly without special tools.

- Less Water Consumption: Uses only the process fluids—no extra cooling tower water or large pumping systems needed.

- Flexible Operation: Can be expanded by adding more plates to increase capacity. Works well for varying temperature and flow conditions.

- Lower Operating Costs: No need for cooling tower chemicals, large pumps, or extensive piping.

Where Are Plate Type Heat Exchanger Used?

- HVAC Systems: Heating and cooling in commercial buildings. District heating systems for transferring heat between networks.

- Food & Beverage Industry: Pasteurization of milk, juices, beer, and other beverages. Heating or cooling sauces, soups, and edible oils without contamination.

- Dairy Processing: Rapid cooling of milk after collection. Heat recovery in dairy pasteurization processes.

- Chemical & Petrochemical Plants: Cooling chemical solutions and solvents. Heat recovery from process streams to save energy.

- Marine Applications: Used for cooling engine jacket water, lubricating oil, and various other critical onboard systems.

How Is a Plate Type Heat Exchanger Constructed?

1. Plates

- Material: Usually stainless steel for corrosion resistance and good heat transfer.

- Shape: Thin, corrugated (wavy) surface to increase turbulence and surface area.

- Each plate has port holes at the corners for fluid entry and exit.

Gaskets or Seals

- Placed around the plates to seal the fluid paths and prevent mixing.

- Direct each fluid into its own flow channel.

- Made from rubber-like materials such as NBR or EPDM.

Frame

- Holds the plate pack together under pressure.

- Two main parts:

- Fixed frame plate – stationary and holds the first plate.

- Movable pressure plate – can be tightened or loosened to add/remove plates.

Tie Bars & Bolts

- Heavy-duty bolts compress the plates together to ensure proper sealing.

- Can be loosened for cleaning or plate replacement.

End Connections / Nozzles

- Fitted with inlet and outlet ports to allow both hot and cold fluids to enter and exit efficiently.

- Located on the fixed frame plate or both ends, depending on design.

What Types of Plate Type Heat Exchanger Exist?

Gasketed Plate Heat Exchanger (GPHE)

- Plates sealed with gaskets that guide the fluids and prevent mixing.

- Can be opened for cleaning or adding/removing plates.

- Common in: Food & beverage, HVAC, dairy, pharmaceuticals.

Brazed Plate Heat Exchanger (BPHE)

- Plates are permanently brazed together (usually with copper or nickel).

- Common in: Refrigeration, heat pumps, oil cooling, district heating.

Welded Plate Heat Exchanger

- Plates are welded instead of gasketed, allowing for higher temperature and chemical resistance.

- Common in: Chemical plants, oil & gas, corrosive fluid handling.

Semi-Welded Plate Heat Exchanger

- Alternate plates are welded in pairs; others use gaskets.

- Designed to be compact, tightly sealed, and capable of withstanding high pressures and temperatures.

- Common in: Chemical processing, ammonia refrigeration.

Plate & Frame Heat Exchanger

- Gasketed plates mounted in a heavy-duty frame.

- Easy to expand or service.

- Common in: Large-scale industrial and HVAC systems.

How to Select the Right Plate Type Heat Exchanger?

Define the Purpose

- Are you heating, cooling, condensing, or pasteurizing?

- Different applications require different plate designs and materials.

Know Your Fluids

- Type of fluids: Water, oil, milk, chemicals, refrigerants, etc.

- Corrosiveness: Aggressive fluids may need stainless steel 316, titanium, or special alloys.

- Viscosity: Thick fluids may need wider channels.

Set Temperature & Pressure Requirements

- Operating temperature range (both hot and cold sides).

- Operating and design pressure (to ensure safety and durability).

Determine Flow Rates

- Calculate how much fluid will pass through each side per hour.

- This sets the specifications for plate size, total plate count, and port diameter.

Choose the Right Plate Design

- Herringbone or corrugated design – enhances turbulence and maximizes heat transfer efficiency.

- Wide gap plates: For fibrous or dirty fluids to reduce clogging.

Decide on the Type of PHE

- Gasketed – Offers flexibility, easy cleaning, and is ideal for applications requiring strict hygiene.

- Brazed: Compact and maintenance-free, best for closed-loop systems.

- Welded/Semi-welded: For high pressure, high temperature, or aggressive chemicals.

Consider Maintenance & Cleaning Needs

- If frequent cleaning is required, choose gasketed with easy disassembly.

- For low-maintenance, sealed designs like brazed PHEs are better.

Check Space & Installation Requirements

- Make sure the PHE fits the available area and has room for service access.

Factor in Cost vs. Lifetime Value

- A cheaper unit may cost more in the long run if it’s less durable or efficient.

- Always compare energy efficiency, maintenance needs, and lifespan.

What Are the Advantages of Plate Type Heat Exchanger?

- High Heat Transfer Efficiency: Thin plates and corrugations create turbulence, so heat moves between fluids very quickly.

- Compact Size: Much smaller and lighter than shell & tube exchangers for the same capacity, saving space.

- Easy to Clean & Maintain: In gasketed PHEs, plates can be removed for manual cleaning or replacement.

- Handles Low Temperature Differences: Can efficiently transfer heat even when hot and cold fluids have small temperature gaps.

- Low Fluid Volume Requirement: Needs less fluid to operate, making start-up faster and reducing energy loss.

- Versatile Applications: Works with water, oils, chemicals, dairy, beverages, and more.

- Energy Efficient: Maximizes heat recovery, reducing overall energy consumption in processes.

How to Maintain Plate Type Heat Exchanger?

Regular Inspection

- Check for leaks around gaskets.

- Look for signs of corrosion or damaged plates.

- Ensure tightening bolts are secure but not over-tightened.

Cleaning

- CIP (Clean-in-Place): Use a chemical cleaning solution to remove scale, oil, or fouling without dismantling.

- Rinse thoroughly to prevent chemical residue.

Gasket Care

- Inspect gaskets for wear, cracks, or hardening.

- Replace damaged gaskets immediately to prevent leaks.

- Use the right gasket material for the fluid type and temperature.

Plate Care

- Avoid scratching or bending plates during cleaning.

- If plates are heavily fouled or damaged, replace them.

- Use only compatible cleaning chemicals to avoid metal damage.

Proper Tightening

- Follow the manufacturer’s torque guidelines when tightening bolts.

- Uneven tightening can cause leaks or damage plates.

Define the Future of Plate Type Heat Exchanger

The future of Plate Type Heat Exchangers lies in greater efficiency, compact design, and smarter operation to meet the rising global demand for energy savings, sustainability, and high-performance heat transfer. Advancements in materials, manufacturing, and digital monitoring will allow PHEs to handle higher temperatures, pressures, and corrosive fluids with minimal maintenance.

In the coming years, we can expect:

- Advanced Alloys & Coatings – Better resistance to corrosion, scaling, and fouling.

- Smart Sensors & IoT Integration – Real-time monitoring of temperature, pressure, and flow for predictive maintenance.

- Customizable Modular Units – Flexible designs that can be easily scaled or adapted for different industries.

- Wider Industry Adoption – Increased use in renewable energy, desalination plants, food processing, and chemical manufacturing.

What Are the Key Factors That Influence the Performance of Plate Type Heat Exchanger?

-

Plate Design & Pattern

The plate’s corrugation shape and depth influence fluid turbulence, heat exchange efficiency, and the resulting pressure loss. More turbulence = better heat transfer but also higher pumping power needed.

-

Material of Plates & Gaskets

Materials like stainless steel, titanium, or nickel alloys offer different thermal conductivity and corrosion resistance. Gasket material must match the fluid type and temperature to avoid leakage and degradation.

-

Flow Arrangement

Counter-flow offers the highest efficiency, while parallel flow may be less effective but suits specific applications.

-

Temperature Difference (ΔT)

-

Flow Rate of Fluids

Higher flow rates increase turbulence, improving heat transfer but also increasing pressure drop and pumping cost.

What Innovations Are Emerging in the Plate Type Heat Exchanger Industry?

-

Advanced Plate Designs for Higher Efficiency:

New corrugation geometries and hybrid plate patterns increase turbulence without drastically increasing pressure drop. Optimized chevron angles to balance heat transfer and pumping cost.

-

Use of High-Performance Materials:

Materials like titanium, Hastelloy, duplex stainless steel, and other advanced alloys are used for exceptional corrosion resistance in demanding chemical and marine environments. Graphite-coated plates for handling highly aggressive fluids.

-

Gasket-Free & Welded Plate Heat Exchangers:

Eliminating gaskets in certain designs allows operation under higher temperatures and pressures. Fully welded and brazed PHEs used for applications like refrigeration, oil & gas, and high-pressure processes.

-

Modular & Compact Designs:

Easily expandable units that allow adding or removing plates to adjust capacity. Space-saving compact heat exchangers for urban industrial plants.

-

Smart Monitoring & IoT Integration:

Sensors to track temperature, pressure, and fouling rate in real-time.

Why Should You Consider Partnering with a Specialized Manufacturer?

-

Tailored Solutions for Your Application

- Specialized manufacturers have deep industry knowledge and can design PHEs suited to your exact thermal requirements, fluid properties, and space constraints.

- They can offer custom plate patterns, gasket types, and materials to match unique process conditions.

-

Higher Quality and Reliability

- Specialist suppliers follow strict manufacturing standards (e.g., ISO, ASME) ensuring consistent quality.

- Better material selection reduces risks of corrosion, fouling, or premature failure.

- Comprehensive quality checks—including pressure, leak, and performance testing—ensure reliable, long-term operation without unexpected failures.

-

Access to Advanced Technology

- Experienced manufacturers invest in R&D and innovations such as improved plate geometries, energy-efficient designs, and CIP-friendly layouts.

- This ensures your PHE is future-ready with the latest performance-enhancing features.

-

Expert Installation and Commissioning

- A specialized manufacturer not only delivers the equipment but also assists with correct installation, ensuring optimal flow distribution and sealing.

- Proper commissioning reduces startup issues and prolongs equipment life.

-

Comprehensive After-Sales Support

- Specialists provide technical assistance, spare parts, and maintenance services over the product’s life cycle.

- Quick access to OEM parts ensures repairs maintain the original performance levels.

Where to buy plate type heat exchanger?

- You can buy Plate Heat Exchangers directly from United Cooling Systems Pvt. Ltd., a reputed manufacturer and supplier based in Coimbatore, Tamil Nadu, India.

-

How to Buy from United Cooling Systems:

- Official Website: Visit their website to explore products and get contact details.

- Contact: Reach out via phone or email for inquiries and custom orders.

- B2B Portals: They are also listed on major Indian B2B marketplaces like Trade India and IndiaMART.

- Direct Visit: If you’re nearby, you can visit their manufacturing unit in Coimbatore for consultations and purchases.

Get in Touch

If you’re seeking a reliable, high-performance Plate Type Heat Exchanger, United Cooling Systems Pvt. Ltd. stands out as a trusted choice. With decades of experience, advanced manufacturing facilities, and a strong focus on customization, they provide durable and efficient solutions for industries ranging from chemical processing to marine applications. Whether you buy directly from their Coimbatore units or through B2B portals, you can count on their quality, technical expertise, and after-sales support for long-term performance.

-

What types of Plate Type Heat Exchangers does United Cooling Systems offer?

They manufacture gasketed, brazed, and semi-welded plate heat exchangers to suit various industrial needs.

-

Can I order custom-designed Plate Heat Exchangers?

Yes. They specialize in designing units based on your process requirements, flow rates, and operating conditions.

-

Do they provide after-sales service?

Yes. United Cooling Systems offers installation guidance, maintenance, and spare parts support.

-

Where is United Cooling Systems located?

They are based in Coimbatore, Tamil Nadu, India.

-

How do I place an order?

You can contact them directly via phone, email, or inquiry forms on their official websites, or place requests through B2B portals like Trade India.