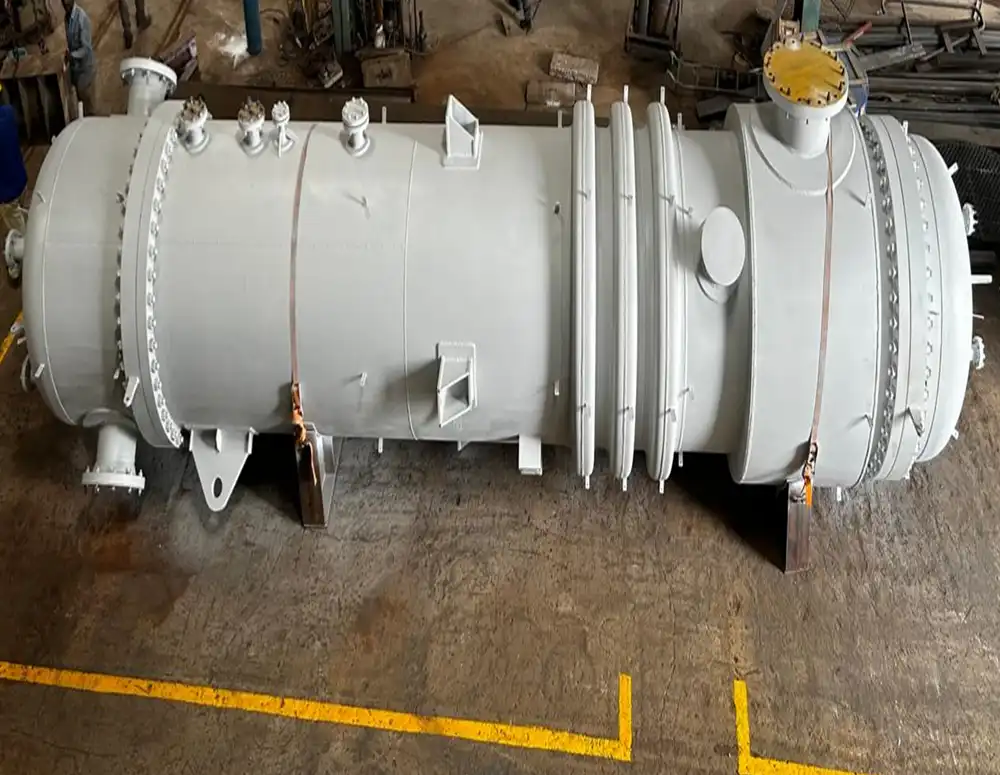

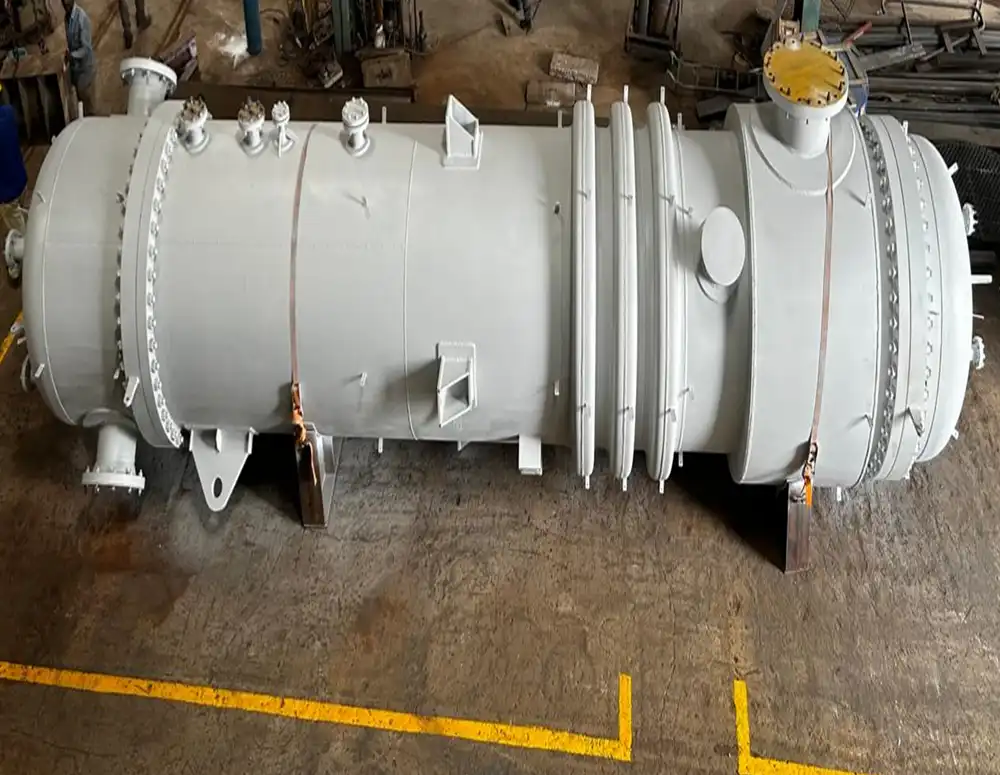

Shell and Tube Heat Exchanger

A shell and tube heat exchanger is a device used to transfer heat between two fluids without mixing them.

It consists of a series of tubes housed inside a larger cylindrical shell.

One fluid flows through the tubes, and the other flows around the tubes within the shell.

Heat moves from the hotter fluid to the cooler one through the metal walls of the tubes.

This type of heat exchanger is widely used in industries like oil refining, power generation,

chemical processing, and HVAC systems because it can handle high pressures, high temperatures,

and large flow rates.

How Does a Shell and Tube Heat Exchanger Work?

A shell and tube heat exchanger works by allowing two fluids to exchange heat without touching each other.

One of the fluids moves through a series of metal tubes.

The other fluid flows around those tubes, inside a larger outer shell.

The metal walls of the tubes let heat pass through from the hotter fluid to the cooler one.

For instance, when hot water moves through the tubes and cold water circulates around them in the shell,

heat passes from the hot to the cold water, increasing the cold water's temperature while reducing the heat of the hot water.

Inside the shell, there are plates called baffles. These baffles help guide the flow of the fluid and make the heat transfer more efficient.

By the time they exit the exchanger, one fluid has absorbed heat while the other has released it.

This system is commonly used in factories, power plants, and large cooling systems.

Define: Shell and Tube Heat Exchanger

A shell and tube heat exchanger is a device used to transfer heat from one fluid to another.

It consists of two primary components: a set of tubes and an outer shell that encases them.

One fluid flows through the tubes, while the other flows around the tubes inside the shell.

The two fluids never mix, but heat moves between them through the tube walls.

This design allows efficient heating or cooling in many industrial processes.

What Are the Main Parts of a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger is made up of several important components that work together to transfer heat effectively. Here are the main parts:

-

Tubes

These are small metal pipes where one of the fluids flows. They are usually made from materials that conduct heat well, like stainless steel or copper.

-

Shell

The shell is a large outer casing that surrounds the tube bundle. The second fluid flows through the shell, around the tubes.

-

Tube Sheets

These are flat metal sheets positioned at both ends of the tube assembly. The tubes are fixed into these sheets to keep them in place and to prevent the fluids from mixing.

-

Baffles

Baffles are metal plates placed inside the shell. They direct the fluid flow over the tubes in a zig-zag pattern, which improves heat transfer and supports the tubes.

-

Inlet and Outlet Nozzles

These are the openings where the fluids enter and exit the exchanger. There are usually two nozzles for each fluid—one for entry and one for exit.

-

Tie Rods and Spacers

These hold the baffles in place and keep them evenly spaced inside the shell.

-

End Covers or Heads

These are the caps on each end of the heat exchanger. They control the flow of fluid as it enters and leaves the tube section of the exchanger.

How Is Heat Transferred in a Shell and Tube Exchanger?

- One fluid flows inside the tubes, while another fluid flows around the outside of the tubes inside the shell.

- The two fluids never mix; they are separated by thin metal tube walls that conduct heat efficiently.

- If the fluid inside the tubes is hotter, it transfers heat to the tube walls.

- The cooler fluid outside the tubes absorbs this heat from the metal walls.

- This heat exchange continues as both fluids move through the exchanger, with one fluid heating up and the other cooling down.

- The use of baffles inside the shell improves flow direction and enhances heat transfer efficiency.

What Is the Design Principle of a Shell and Tube?

The basic idea behind the design is to let two fluids exchange heat without coming into direct contact.

One fluid flows inside a set of tubes, while the other flows around those tubes within an outer shell.

Heat moves from the hotter fluid to the cooler one through the tube walls.

The design focuses on:

- Keeping the fluids separate while allowing heat to pass between them

- Maximizing surface area using many tubes to increase heat transfer

- Controlling the flow paths so the fluids move efficiently and exchange heat effectively

- Using materials that can handle the temperature, pressure, and type of fluid involved

The goal is to create a system that transfers heat as efficiently as possible,

while staying safe, easy to maintain, and suitable for long-term use in industrial settings.

How Do You Calculate Shell and Tube Performance?

To understand how well a shell and tube heat exchanger is working, you need to look at how much heat is being transferred from one fluid to another.

This is usually calculated using a few basic formulas.

1. Heat Transfer Rate (Q)

This tells you how much heat is being exchanged. It’s calculated using this formula:

Q = m × Cp × ΔT

Where:

- Q = Heat transferred (in Watts or kW)

- m = The amount of fluid flowing per second (kg/s)

- Cp = Specific heat of the fluid (J/kg·°C)

- ΔT = Temperature change (°C) between fluid entry and exit

You can calculate this for both fluids (tube side and shell side) and compare the results.

2. Log Mean Temperature Difference (LMTD)

This is used when the temperature difference between fluids changes along the exchanger length. The formula is:

LMTD = (ΔT₁ - ΔT₂) / ln(ΔT₁ ÷ ΔT₂)

Where:

- ΔT₁ = Temperature difference at one end

- ΔT₂ = Temperature difference at the other end

- ln = Natural logarithm

3. Overall Heat Transfer Equation

Once you have LMTD, you can use it in the main heat transfer formula:

Q = U × A × LMTD

Where:

- Q = Heat transferred

- U = Overall heat transfer coefficient (W/m²·°C)

- A = Surface area of the tubes (m²)

- LMTD = Log Mean Temperature Difference

4.

Effectiveness

Sometimes, performance is measured in terms of how close the exchanger gets to ideal heat transfer.

This is called effectiveness (ε) and is defined as:

Effectiveness = Actual heat transferred / Maximum possible heat transfer

These calculations help engineers evaluate whether the exchanger is working properly,

or if it needs cleaning, resizing, or design adjustments.

What Fluids Are Used in Shell and Tube?

Shell and tube exchangers can handle a wide variety of fluids, depending on the process they’re used in.

These fluids can be gases or liquids, and they are chosen based on temperature needs, flow rate, and safety requirements.

Some common examples include:

- Water – Widely used for both cooling and heating.

- Steam – A popular choice when heat needs to be transferred quickly.

- Oils – Used when higher temperatures are needed, such as in industrial heating systems.

- Air and industrial gases – Used in gas processing or chemical plants.

- Chemical solutions – Many industrial processes use acids, solvents, or process chemicals.

- Refrigerants – Often found in systems involving cooling or refrigeration.

These fluids are selected carefully to match the system’s design, operating pressure, and temperature range,

ensuring safe and efficient operation.

Where Are Shell and Tube Used?

Shell and tube heat exchangers are commonly applied across various industries to heat or cool different types of fluids.

They are known for their durability, efficiency, and ability to handle high pressure and temperature.

Common places they are used include:

- Oil and Gas Refineries – To cool or heat oil, gas, and other fluids during processing.

- Power Plants – Used in boilers, condensers, and other systems to manage heat flow.

- Chemical Industries – To maintain precise temperatures in reactions or to recover heat from waste fluids.

- Pharmaceutical Manufacturing – For temperature control during production processes.

- Food and Beverage Processing – Employed in processes like pasteurizing, sterilizing, and chilling liquids.

- HVAC Systems – Used in chillers and central heating systems to manage temperature in large buildings.

Because of their flexible design and strong performance, they are a common choice in both heavy industrial and commercial settings.

How Does It Compare to Other Heat Exchangers?

Shell and tube exchangers are one of several types of heat exchangers used in industries.

Compared to Plate Heat Exchangers

- Shell and Tube: Well-suited for demanding conditions involving high pressure and temperature.

- Easier to clean on the tube side.

- Plate Type: More compact and efficient for smaller duties but less suitable for very high pressures.

Compared to Air Cooled Exchangers

- Shell and Tube: Uses water, steam, or other fluids. More compact in size.

- Air Cooled: Uses ambient air as the cooling medium. Ideal where water is scarce.

Compared to Double Pipe Exchangers

- Shell and Tube: Handles larger flow rates and heat duties. Better for industrial scale.

- Double Pipe: Simpler design, good for small flow systems but not space-efficient for large operations.

Compared to Spiral Exchangers

- Shell and Tube: Simpler to service and commonly used across industries.

- Spiral: Better for fouling fluids but harder to clean and less common.

How Is a Shell and Tube Installed?

Installing a shell and tube heat exchanger involves several important steps to make sure it works safely and efficiently. Here's a basic overview:

1. Site Preparation

- A solid, level foundation is needed to support the weight of the equipment.

- The area should allow space for maintenance and easy access to pipe connections.

2. Positioning the Exchanger

- The heat exchanger is lifted and carefully placed using cranes or hoists.

- It is aligned horizontally or vertically, depending on the design and piping layout.

3. Mounting and Securing

- The exchanger is fixed to the base using support brackets or anchor bolts.

- Expansion joints or sliding supports may be used to handle thermal movement.

4. Connecting the Piping

- Inlet and outlet lines for both fluids are connected to the nozzles.

- Proper gaskets, flanges, or threaded connections are used to prevent leaks.

5. Insulation (Optional)

- Insulation may be added around the shell or piping to reduce heat loss or protect workers from hot surfaces.

6. Testing and Commissioning

- Once everything is connected, pressure and leak tests are done.

- The system is started slowly, checking for temperature, flow, and pressure to ensure proper operation.

What Are the Advantages of Shell and Tube?

Shell and tube heat exchangers are widely used because they offer several strong benefits across many industries.

Here are some of the main advantages:

-

Handles High Pressure and Temperature:

They are built to work in tough environments, making them ideal for oil refineries, power plants, and chemical processing.

-

Flexible Design:

They can be made in different sizes and layouts to suit various flow rates, temperature needs, and space requirements.

-

Easy to Clean and Maintain:

The tubes can be accessed for cleaning or replacement, especially in removable tube bundle designs.

-

Durable and Long-Lasting:

Made from strong materials like stainless steel, they can last for many years even under demanding conditions.

-

Supports a Wide Range of Fluids:

They can handle gases, liquids, oils, steam, and even corrosive chemicals, depending on the material of construction.

-

Multiple Pass Arrangements:

The fluid can pass through the tubes in different ways (1-pass, 2-pass, etc.) to improve heat transfer efficiency.

-

Can Be Used in Series:

Several units can be connected together to handle higher capacities or more complex processes.

Shell and tube exchangers are a popular choice because they combine reliability, efficiency, and adaptability —

making them suitable for both small and large-scale applications.

What Are the Limitations of Shell and Tube?

While shell and tube heat exchangers are widely used and reliable, they also come with some limitations. Here are a few of the most common ones:

-

Large Size and Space Requirement:

These exchangers can be bulky, especially for high-capacity systems. They need more floor space compared to compact designs like plate exchangers.

-

Heavy Weight:

Due to their metal construction and tube bundles, they can be quite heavy, requiring strong support structures and careful handling during installation.

-

Higher Initial Cost:

Although durable, the upfront cost (especially for large or custom designs) can be higher than simpler alternatives.

-

Difficult Shell-Side Cleaning:

While tubes are accessible, cleaning the inside of the shell can be difficult, especially if the fluid causes fouling.

-

Thermal Expansion Issues:

When operating at high temperatures, the difference in expansion between the shell and tubes can cause stress, requiring special designs like floating heads.

-

Lower Heat Transfer Efficiency (Compared to Plate Exchangers):

In some cases, shell and tube units may be less efficient in transferring heat when compared to newer or more compact designs.

-

Leakage Risks:

If tube sheets or seals fail, there's a risk of fluids mixing, which could be dangerous in sensitive applications.

Despite these limitations, shell and tube exchangers remain a top choice for many industries because of their strength, versatility, and reliability.

How Is Maintenance Performed on a Shell and Tube?

Maintaining a shell and tube heat exchanger is essential for keeping it efficient, safe, and long-lasting. Here's how regular maintenance is typically carried out:

-

Inspection

Visual checks are done to look for signs of leaks, corrosion, vibration, or unusual noises.

Temperature and pressure readings are monitored to detect performance drops.

-

Tube Cleaning

Mechanical Cleaning: Long brushes or rods are used to scrub inside the tubes and remove scale or debris.

Chemical Cleaning: Cleaning agents (like acid or alkaline solutions) are circulated to dissolve dirt and deposits inside the tubes.

-

Shell-Side Cleaning

The shell side is harder to access but can be cleaned using flushing or chemical circulation.

In some designs, partial dismantling is required to access the inner shell areas.

-

Leak Testing

Pressure tests or dye penetrant testing are done to check for tube leaks or cracks.

If any leaks are found, the damaged tubes may be plugged or replaced.

-

Gasket and Seal Checks

Gaskets around the covers or flanges are checked for wear and replaced if needed to prevent fluid mixing.

-

Tube Bundle Removal (if applicable)

In models with removable tube bundles, the entire set of tubes can be taken out for deep cleaning, inspection, or replacement.

-

Reassembly and Testing

Once maintenance is complete, the exchanger is put back together and tested under pressure to ensure it’s ready for operation.

What Are Typical Operating Parameters?

Shell and tube heat exchangers are used across many industries, so their operating conditions can vary. However, here are the typical operating parameters you’ll find in most applications:

Temperature Range

- Inlet/Outlet Temperatures: Commonly from -30°C to 400°C

- Can go higher or lower depending on the materials used (like stainless steel or special alloys)

Pressure Range

- Tube Side: Up to 100 bar or more

- Shell Side: Usually lower, around 10–60 bar

- Exact values depend on the fluid type and application

Flow Rate

Capable of managing flow rates from just a few liters per minute up to thousands of cubic meters per hour.

Heat Duty (Capacity)

From a few kilowatts (kW) to several megawatts (MW), depending on size and design.

Velocity Inside Tubes

Usually 1–3 m/s to ensure good heat transfer without causing tube erosion.

These parameters are carefully selected during the design phase to match the specific needs of the process—ensuring safety, efficiency, and long-term reliability.

Where to buy a shell and tube heat exchanger?

United Cooling Systems is a leading manufacturer of high-performance Shell and Tube Heat Exchangers, trusted across industries for their durability, efficiency, and precision. Each unit is designed to handle a wide range of fluids and temperature conditions, making them suitable for chemical, oil & gas, power, and HVAC applications. With a focus on quality engineering and thermal optimization, their exchangers offer high heat transfer efficiency with minimal maintenance. The company uses premium materials like stainless steel, copper, and brass to ensure long life and corrosion resistance. In addition, United Cooling Systems provides customized solutions, competitive pricing, and dedicated after-sales support, making them a reliable choice for businesses seeking robust and energy-efficient thermal systems.

Get in Touch

Shell and tube heat exchangers remain one of the most reliable and versatile solutions for heat transfer across a wide range of industries. Their ability to handle high pressures, extreme temperatures, and various fluid types makes them a trusted choice for everything from power plants to food processing facilities.

With a simple yet effective design, these exchangers offer easy maintenance, strong durability, and flexible configurations. Whether you need to cool, heat, condense, or vaporize fluids, shell and tube systems provide consistent performance and long service life.

By understanding their working principles, components, advantages, and limitations, industries can make better decisions when selecting the right heat exchanger for their processes. As thermal systems continue to evolve, shell and tube exchangers will remain a key part of efficient and dependable heat transfer solutions.